No products in the cart.

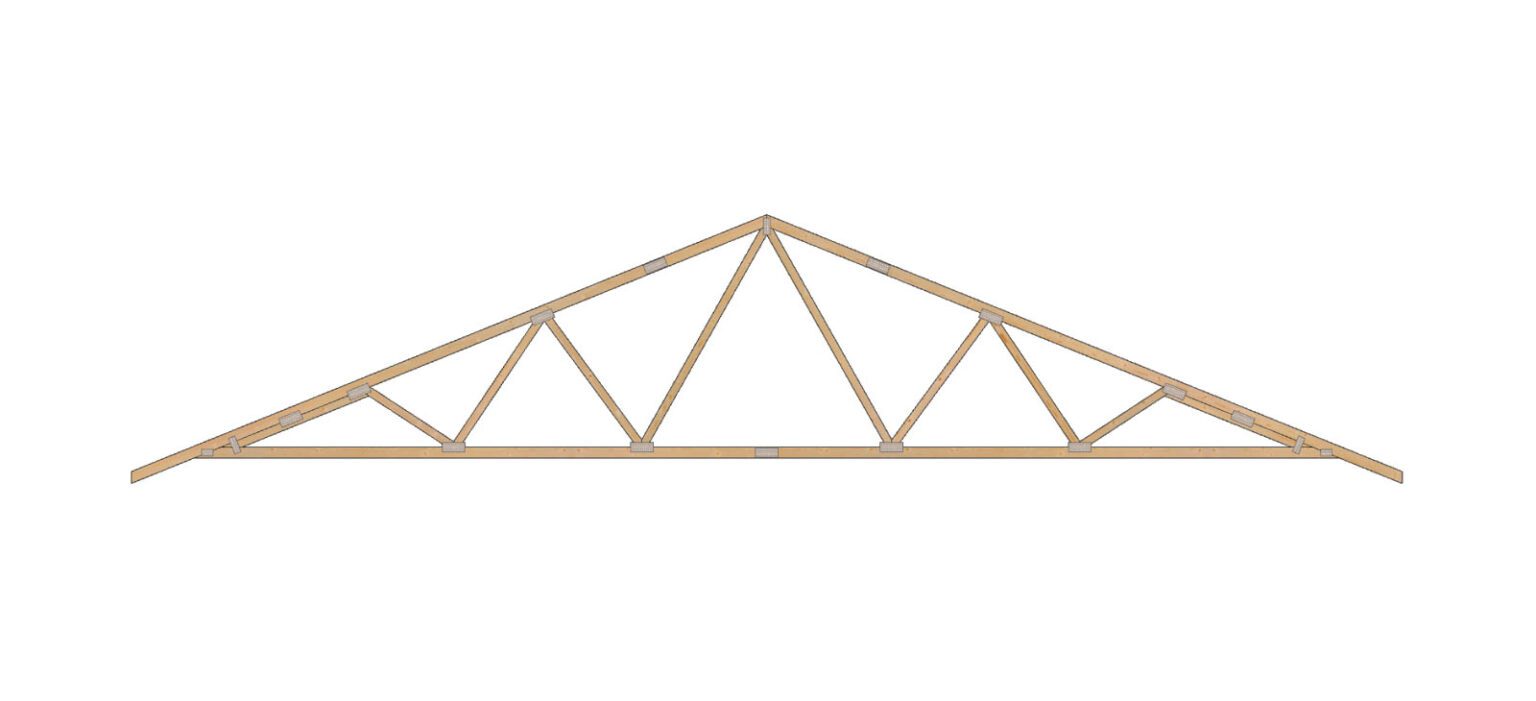

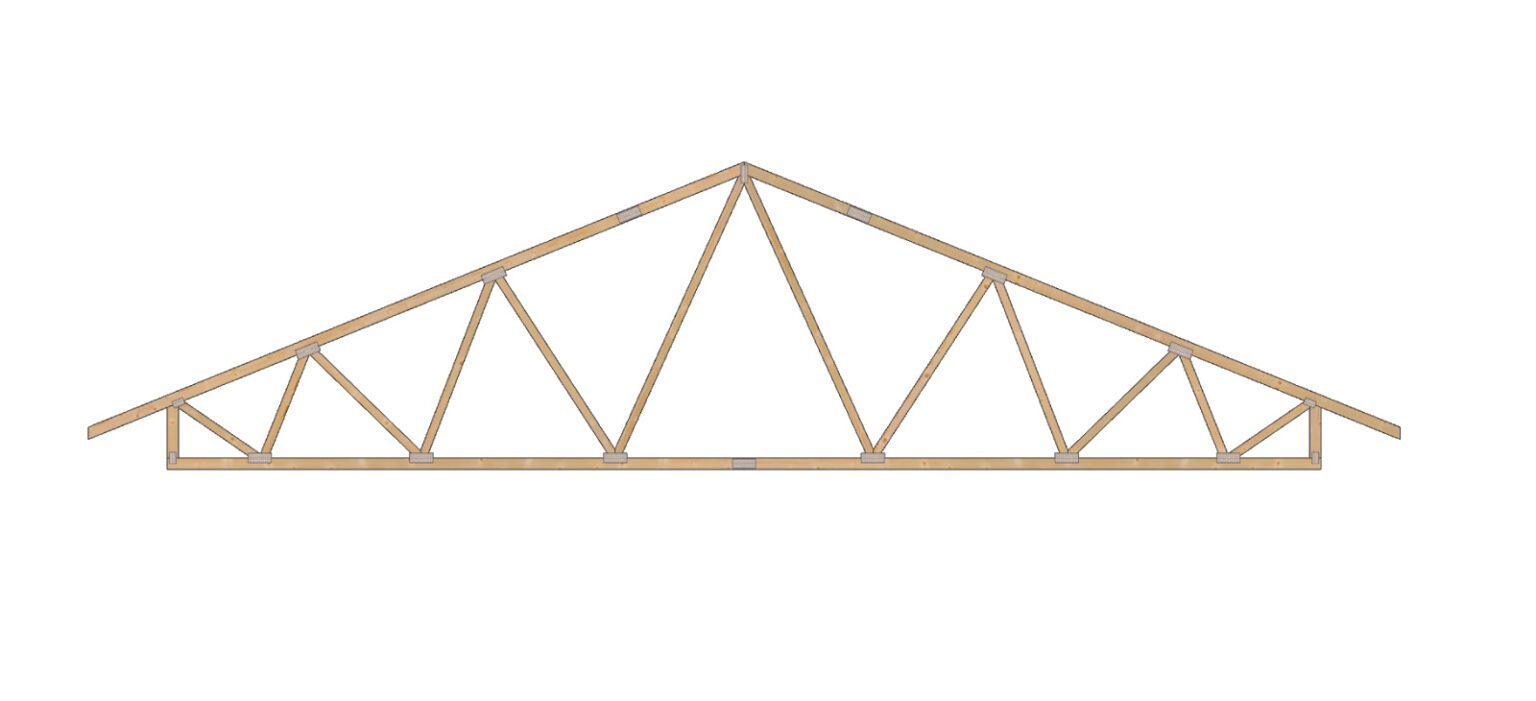

Eco – is the most advantageous type of bus both from the point of view of price and performance. This type of solution has excellent bearing capacity – there is sufficient height instead of the support, the side overhang ledge is created simultaneously with the supporting structure, there is enough space for insulation on the wall, with the possibility of creating larger overhangs, without making the roof structure significantly more expensive.

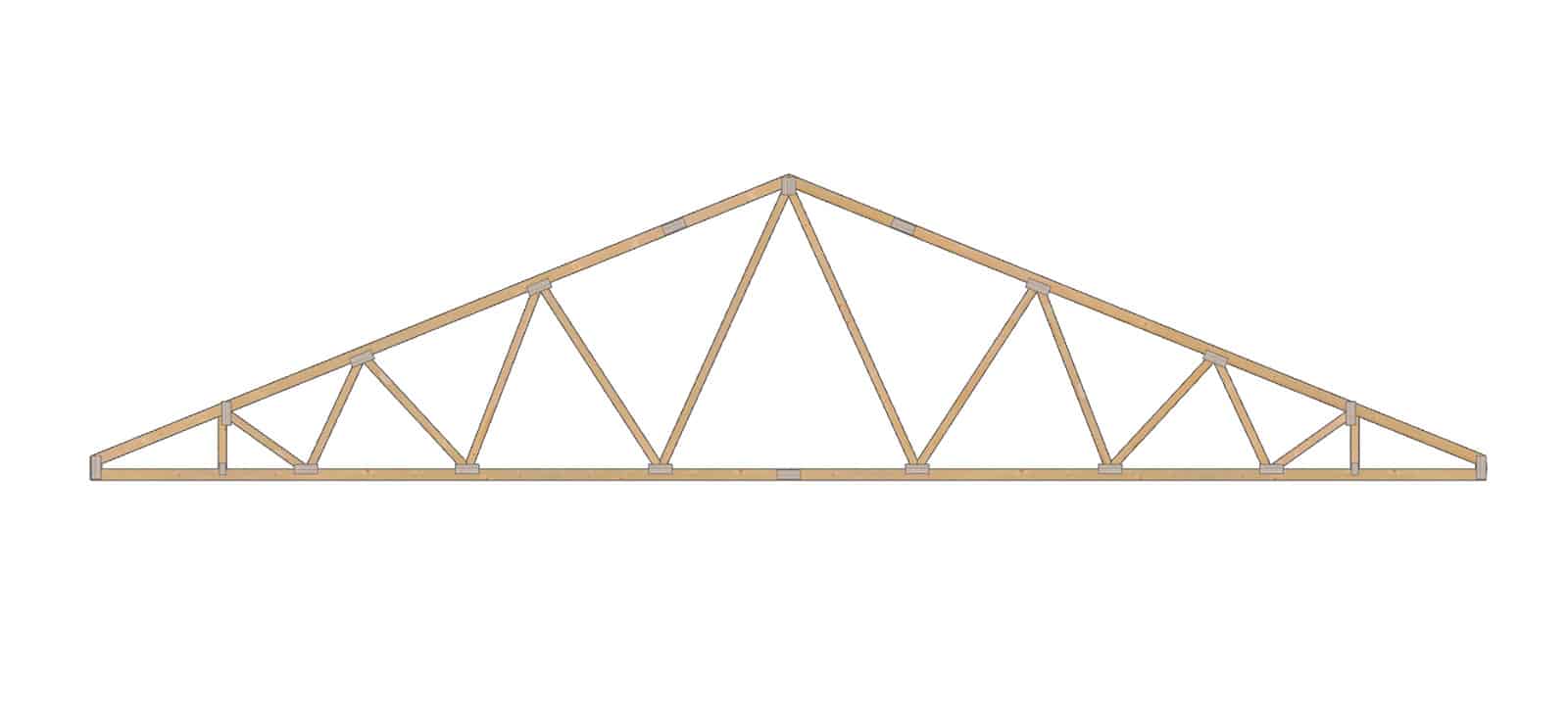

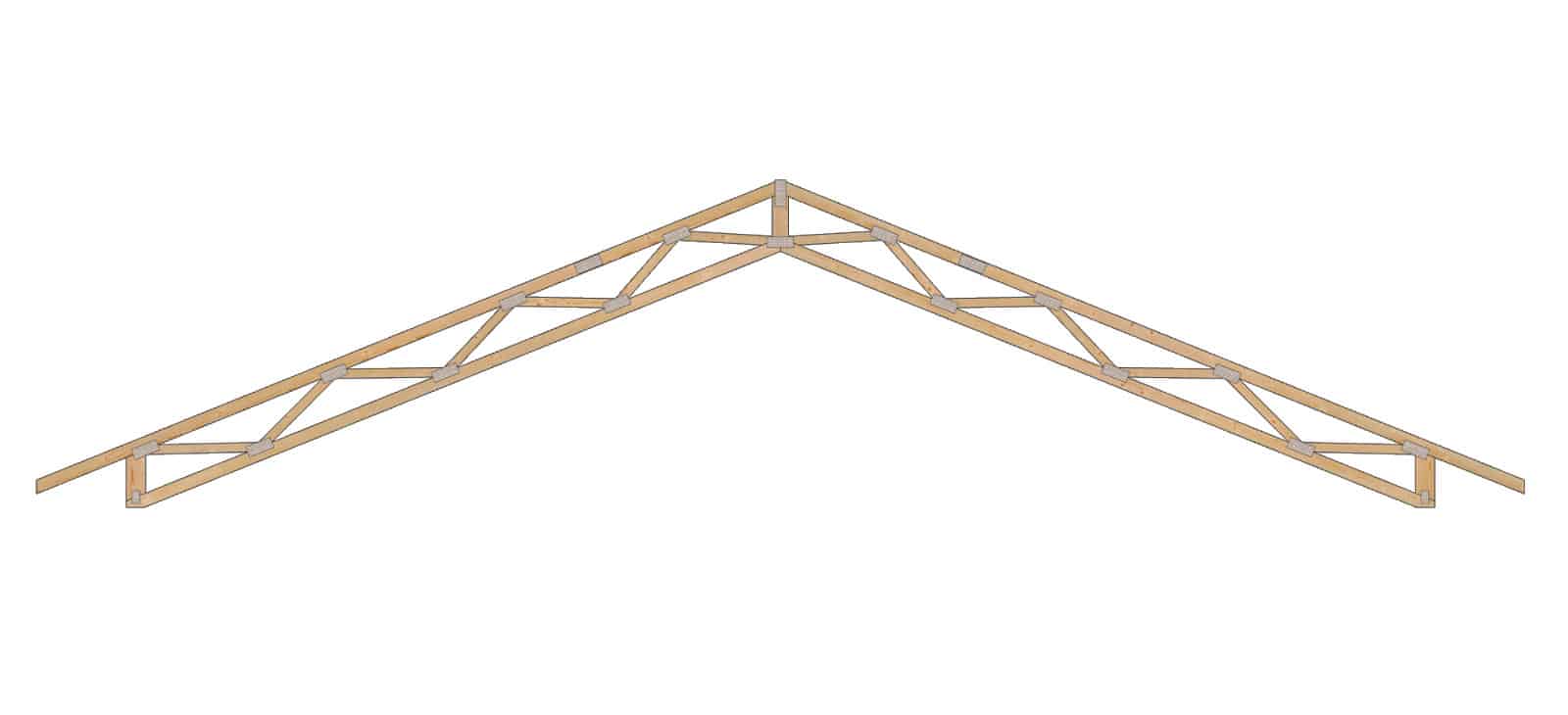

Duo – standard type trusses, can be made up to 35m.

Stubbed duo – Similar to the Duo type truss – With struts at the support points which increase the carrying capacity of the truss. At the same time, it creates the necessary height for the creation of full-fledged insulation in the ceiling.

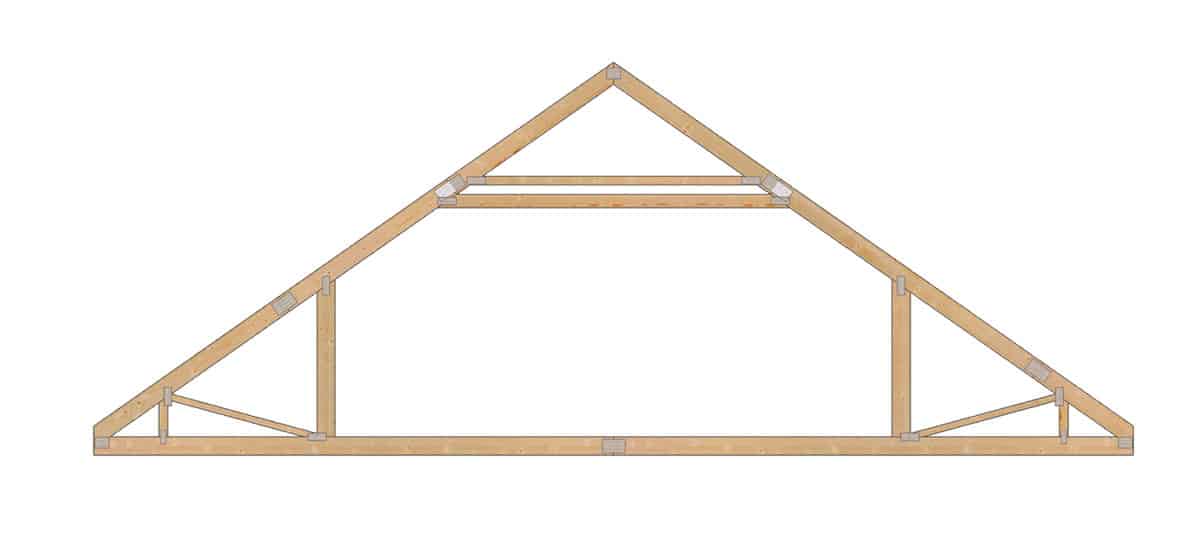

Attic – Mansard-type truss, in the middle part of the truss, it is made without center supports, creating a space for storage of goods or a habitable space.

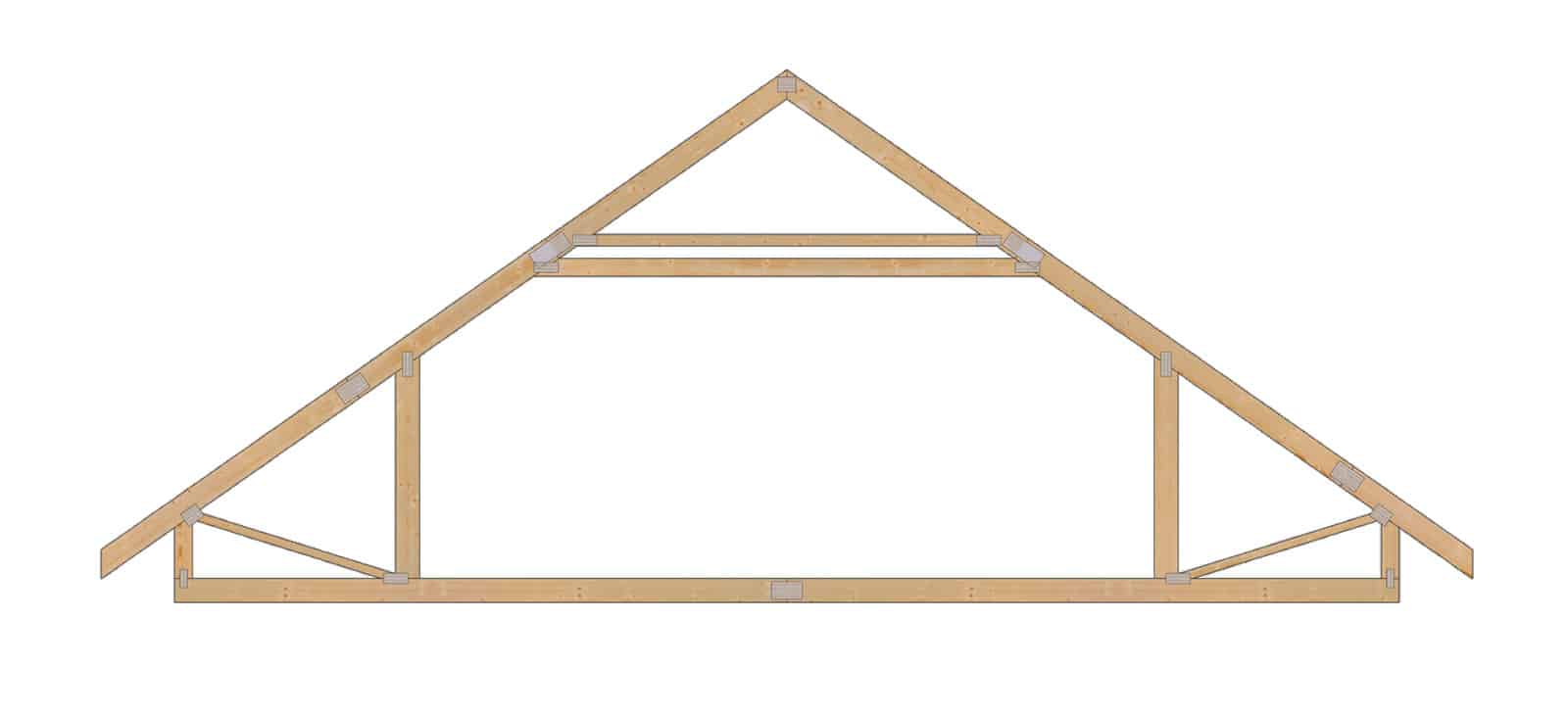

Stubbed attic – Similar to the Attic type truss, but with struts in the support areas, which increase the bearing capacity of the truss.

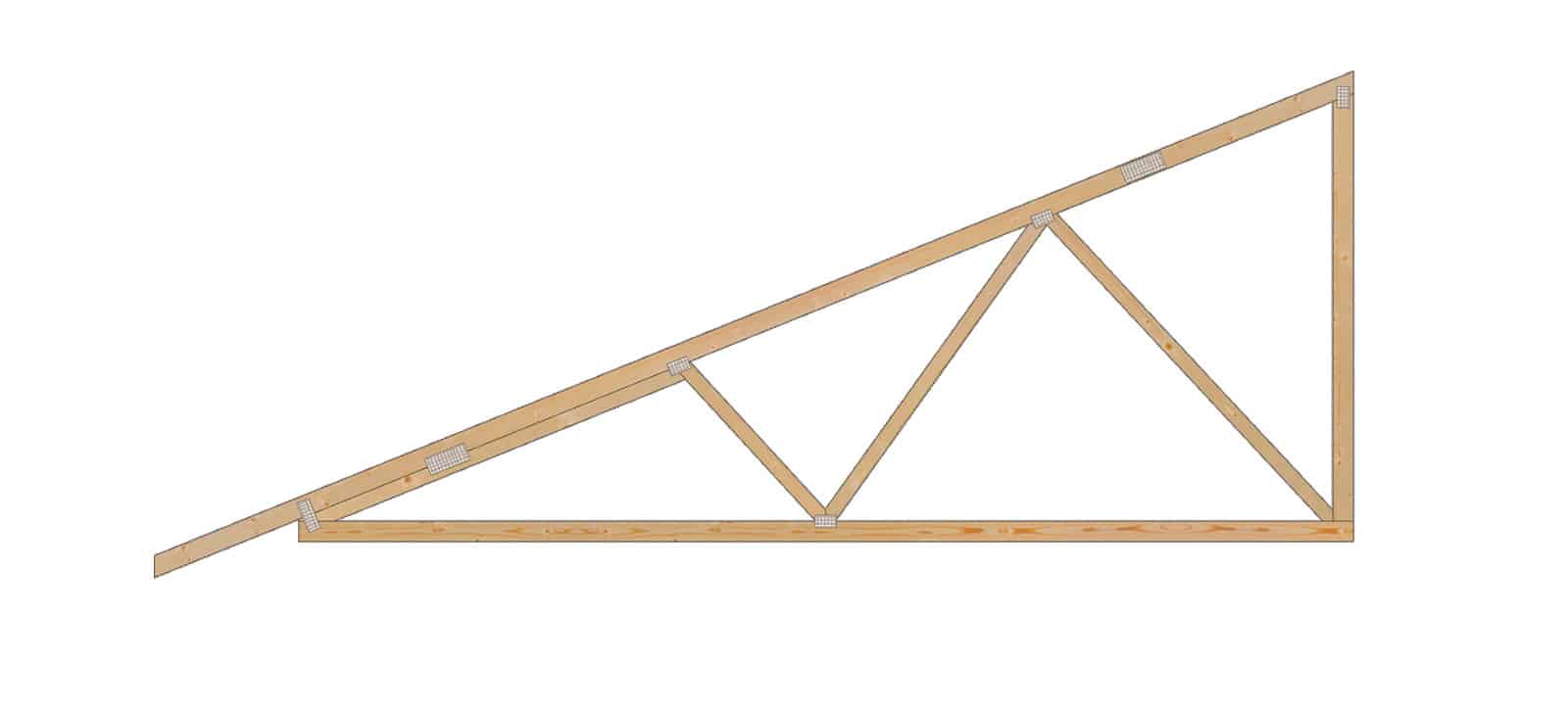

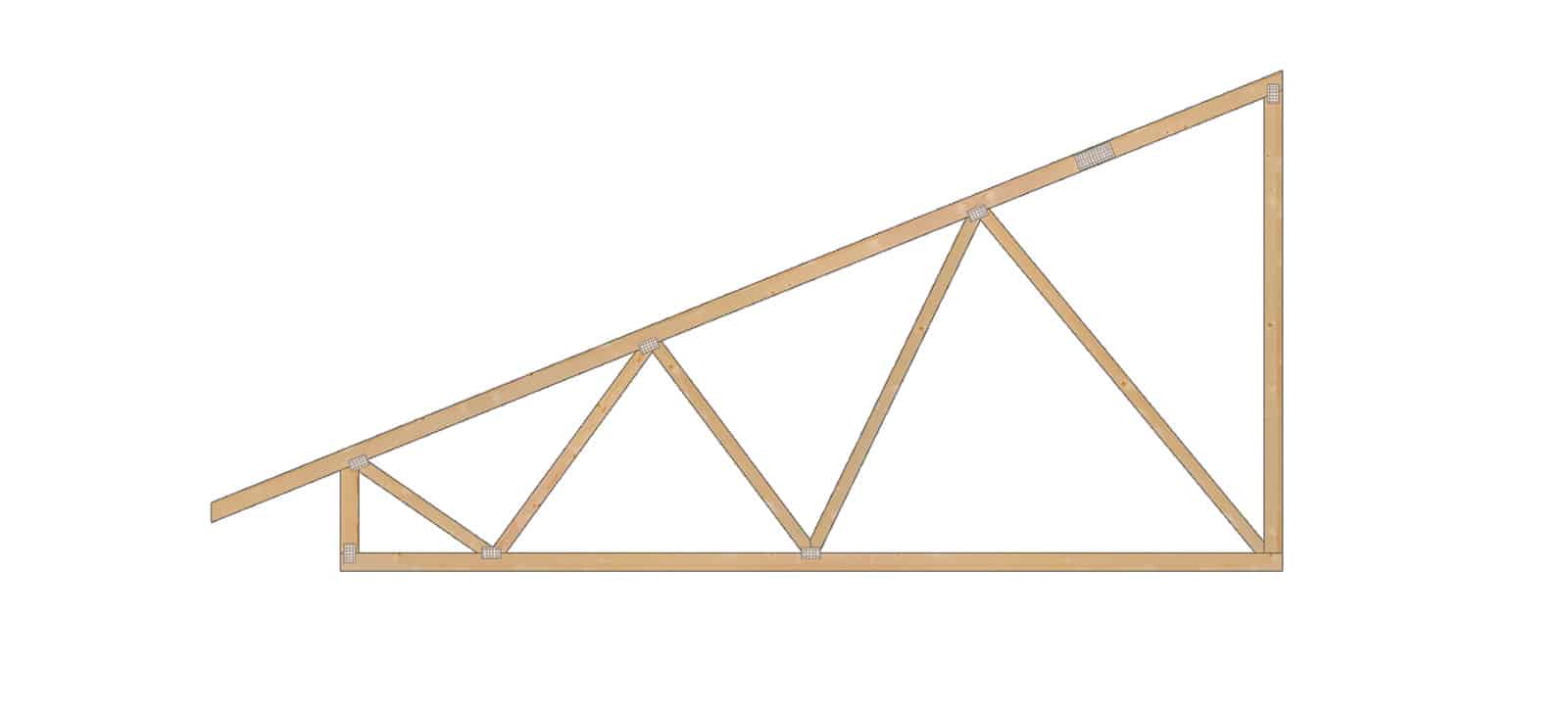

Mono – Used for flat roofs – compared to Duo-type trusses, the carrying capacity of these trusses is relatively lower.

Stubbed mono – Similar to the mono type truss, but with struts at the support points, which increase the carrying capacity of the truss.

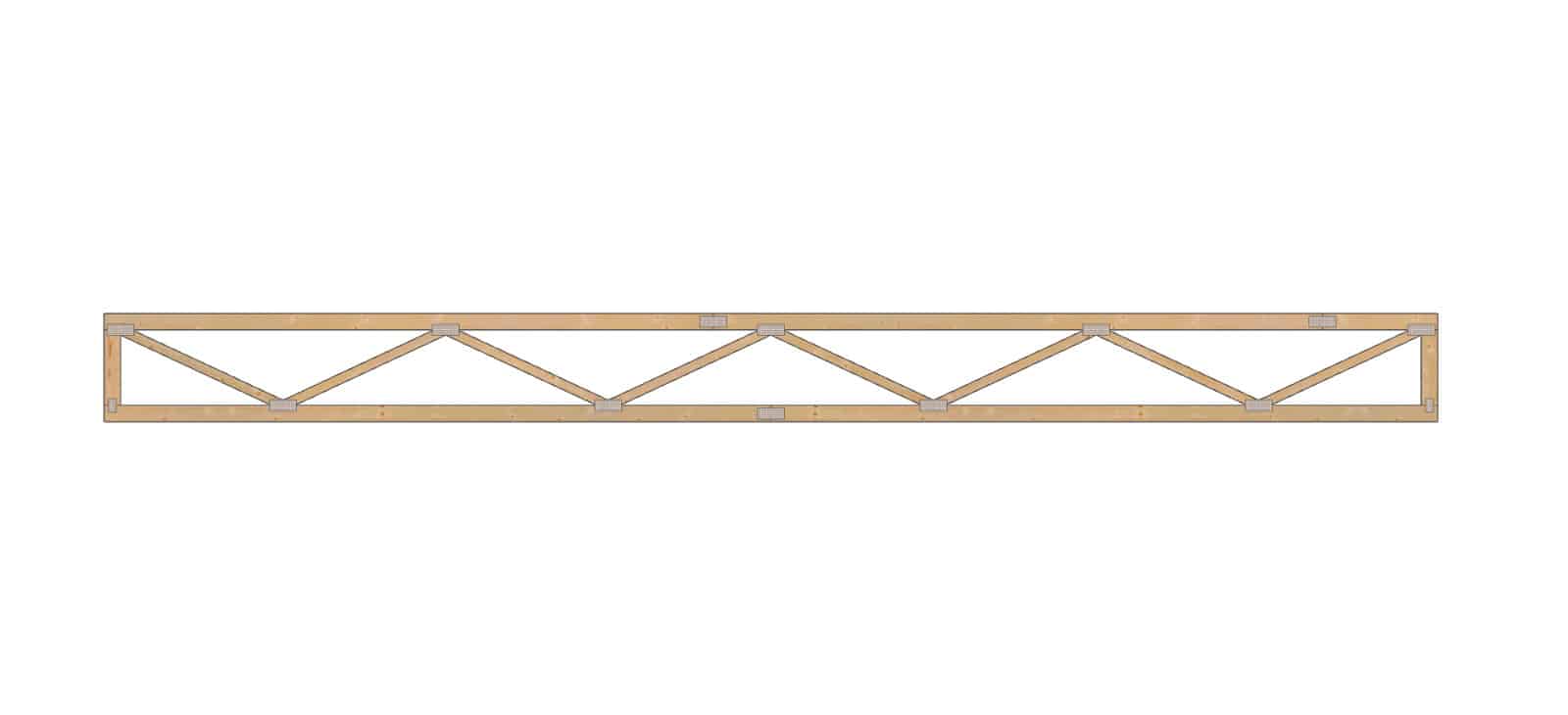

Flat – Trusses are used both as a roof structure (creating the slopes on site at the facility) and as a covering between floors. As an advantage, we can mention that ventilation and other necessary solutions can be mounted through the truss structure.

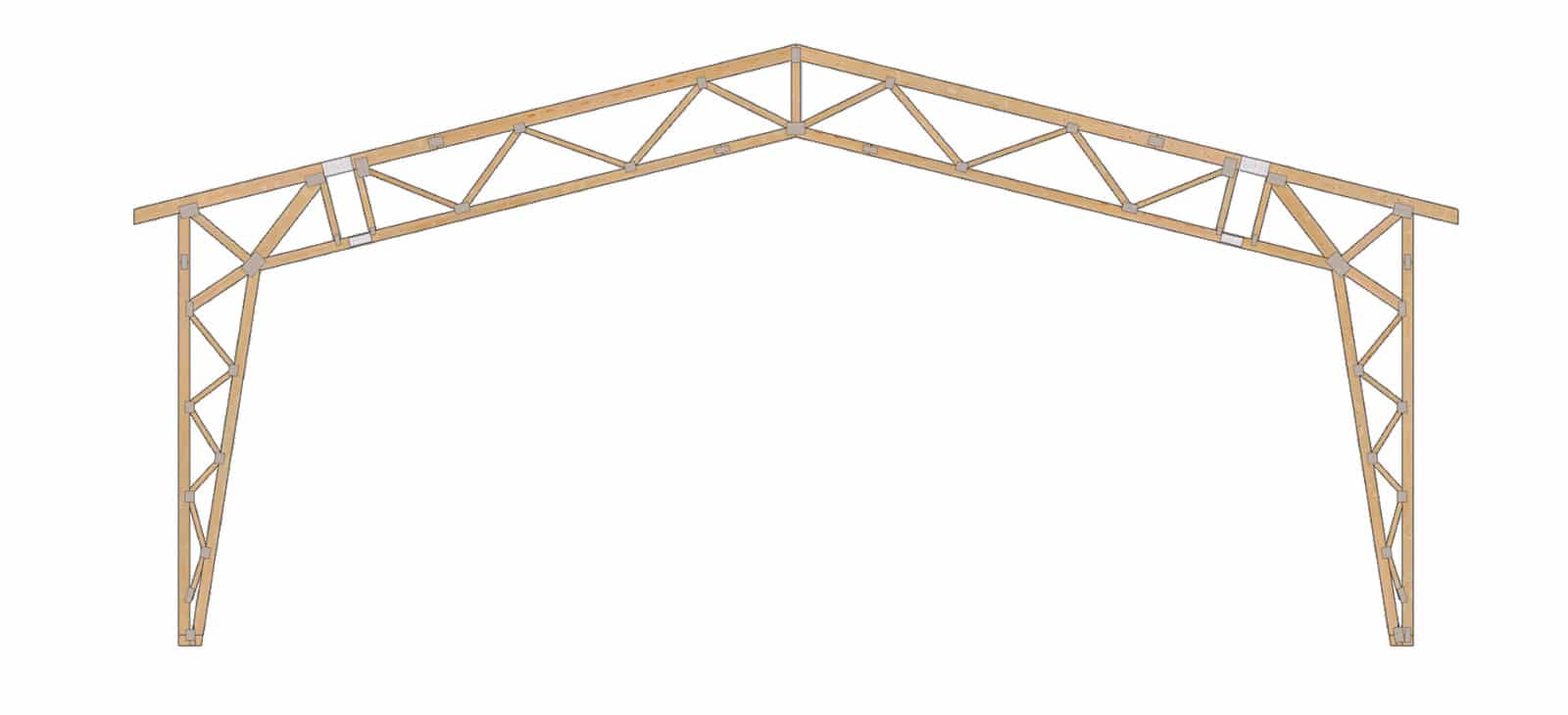

Stubbed modified – Used to create hangar warehouses and other buildings, creating both wall and roof construction. Such solutions are most often made in large spans, and for transportation purposes, the structure is made of several parts, which are strengthened at the site according to the information provided by the manufacturer.

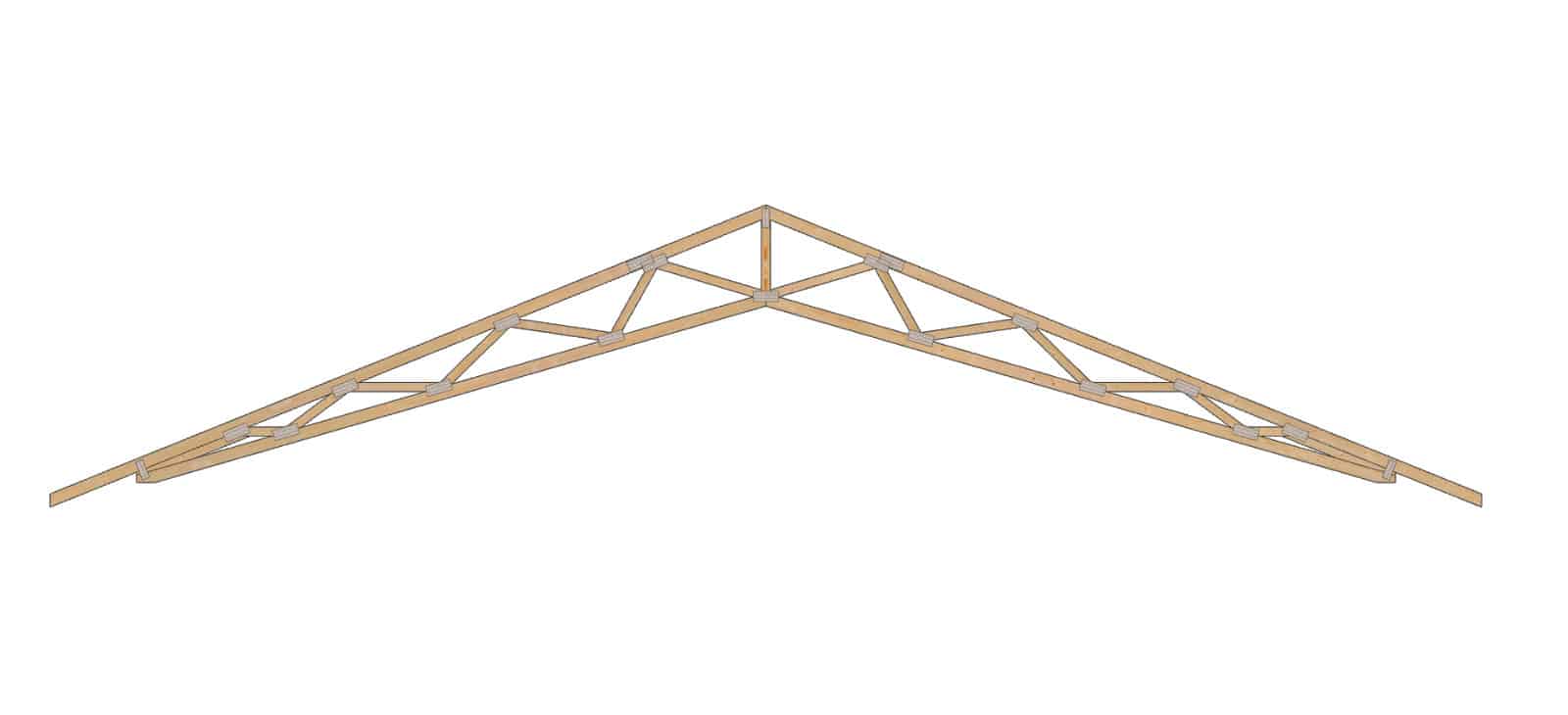

Scissor – Creates a sloping ceiling that creates a sense of a larger space. It is most often used by combining Duo and Scissor trusses, where the Scissor solution is created in the living room, while the Standard type horizontal ceiling is created in the other rooms.

Paralel – This type of construction is used to make the ceiling at the same slope as the roof. There are 2 types of constructions:

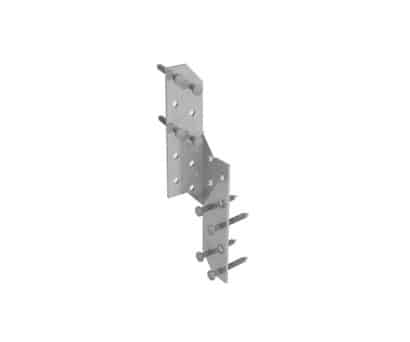

ABR corner plates are used to fasten roof trusses to the wall plate. Central or edge reinforcement is essential for these fastening plates. Special corner screws or corner nails are used for installation.

The BSN roof cleat is used to connect secondary beams to main beams/trusses.

The BSN roof cleat can also be used to support double trusses.

The L170 connection plate is used to join cross beams. The plate absorbs the horizontal forces of the trusses. Depending on the load, the L170 connection plate should be used either twice or four times (installed on the left and right sides).

Corner bracket for fastening wooden trusses together. Used to connect different trusses on a gable roof. The corner bracket is galvanized. Be sure to use all the specified fasteners.

Overview

Composition:

Overview

Composition:

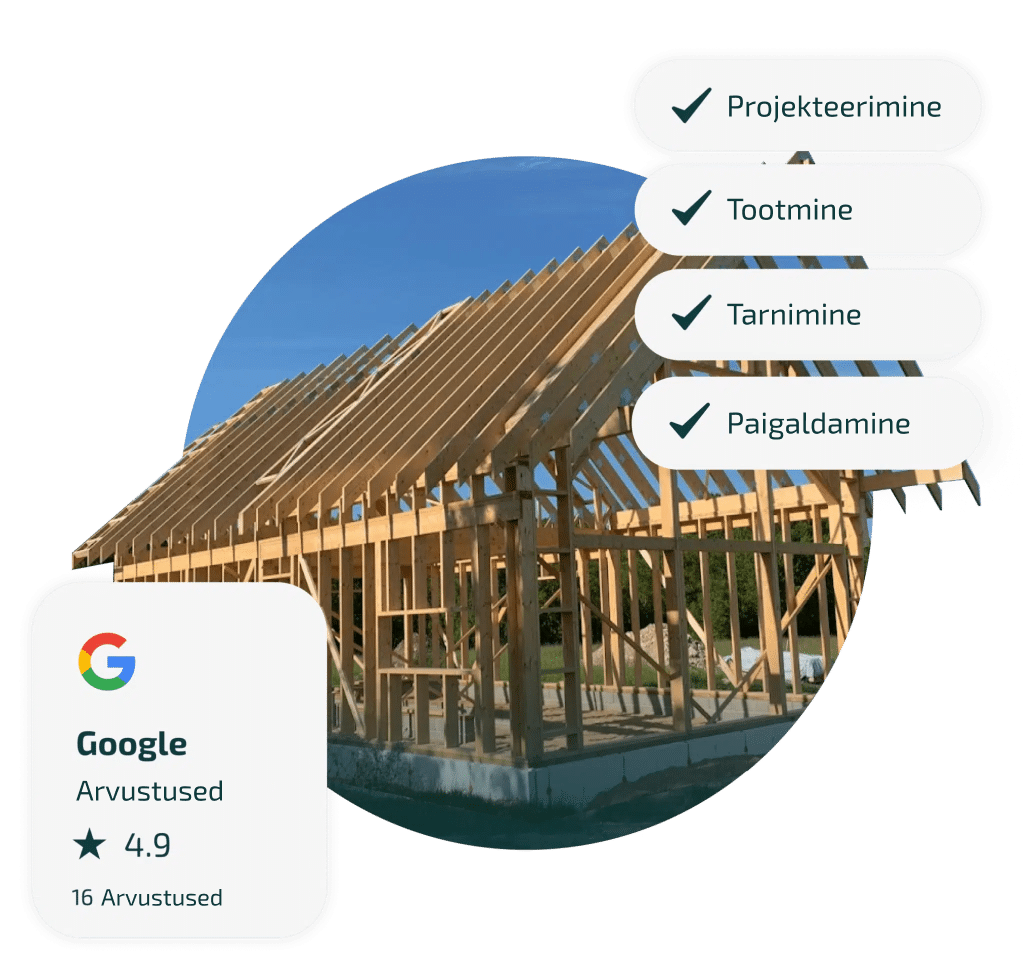

Timber roof trusses are engineered roof structures manufactured off-site to precise specifications. They offer a faster, more efficient, and sustainable alternative to traditional roof framing methods. Tenter's timber trusses are designed to meet all building load requirements and industry standards, ensuring structural integrity and long-lasting performance. We provide a wide range of truss solutions for:

While truss installation is generally straightforward, we recommend relying on our team of experienced professionals. Tenter's installation service ensures your roof structure is assembled quickly and correctly, giving you peace of mind and saving you valuable time.

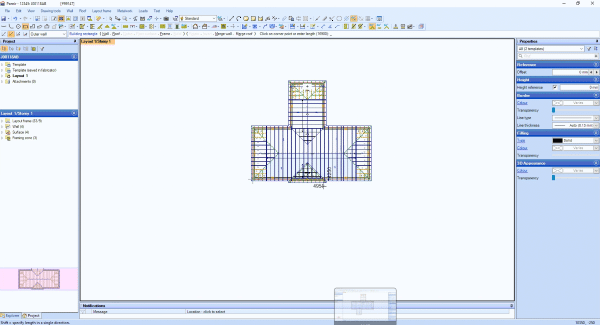

We value your time, and our efficient design process ensures you receive a prompt solution. Our experienced designers utilize advanced PAMIR software to create your custom truss design quickly and accurately.

At Tenter, we understand that every project is unique, so the first step of every project is to create a solution. Our experienced designers have created a significant amount of projects, so we know how to provide solutions that precisely meet the needs of our clients, while at the same time ensuring maximum financial benefit.

You can be sure that Tenter's professional design team will carefully develop a plan that meets load calculation standards, so you don't have to worry about the load-bearing capacity of the roof trusses, because we prioritize safety and compliance of the trusses to a specific building and roof type. In designing, we use PAMIR, a timber truss design software.

Using Tenter's knowledge and advanced technologies, you can always expect a professional approach and quality solutions from our team.

As the largest timber truss producer in the Baltics, Tenter delivers durable, high-quality solutions that create a sustainable and valuable living environment. Our dedicated design and project management team is committed to your satisfaction, ensuring you receive the perfect truss solution for your project needs. We manage the entire process with precision, from design and production to timely delivery and expert installation.

Our manufacturing facility is located in Rummu, a picturesque town in the Harju region. We utilize modern manufacturing practices and adhere to strict quality control measures to ensure every truss meets our high standards.

Tenter offers competitive pricing and cost-effective truss solutions. Our comprehensive packages include design, production, and installation. To receive a personalized quote, please submit an inquiry through our website or contact us directly. We are committed to providing the best value and ensuring your project success.

Strength-Graded Timber EN 14081-1:2005+A1:2011

Estonian Creditors Association – MEMBER NO. 39742

MTR: Design: EEP004719

MTR: Construction: EEH012698