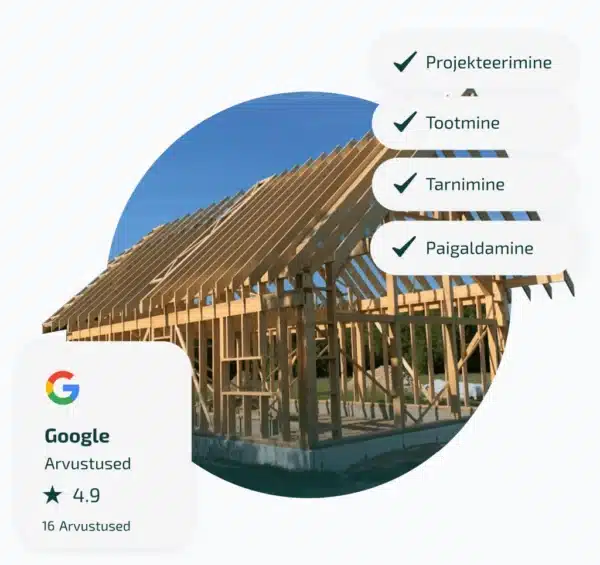

Sustainable solutions

Industrially produced trusses and beams are custom-engineered to meet the exact load requirements of each building (self-load, useful load, wind, snow). This precision results in significant material savings compared to traditional on-site rafter construction. Additionally, installation time is drastically reduced, offering a streamlined building process.

Technologies

Our production process leverages an automated saw line with millimeter-level precision, ensuring accuracy in every cut. Efficiency is further enhanced with a press table system. To guarantee top-tier product quality, a unique laser system (unmatched in the Baltics) projects the finished product's shape directly onto the production table.

Tested quality

Our team of highly skilled and motivated experts meticulously designs, manufactures, and tests every element, module, part, and structure. This dedication ensures optimal performance and reliability in the final product.